Karma Lab is a service provider to the clean manufacturing industry, specializing in cleanroom certification testing, evaluation and consulting services.

We serve customers in many different industries throughout Egypt. We carry with us many years of experience along with current knowledge and the latest test equipment.

Our goal is to provide professional services at a reasonable cost. This simple formula has provided us with a strong client base that we continue to serve year after year.

Certification Means Quality

We support the following standards and practices for the certification of cleanrooms, laminar flow hoods and mini-environments:

- Federal Standard 209E

- ISO 14644-1

- IES-RP-cc006.2

Regular testing of your cleanroom facility should be established on a quarterly, semi-annual or annual basis. The focus of the testing program is to monitor the performance of your facility in order to identify significant changes in efficiency. This will ensure changes can be addressed before they become a major source of contamination effecting productivity. By reviewing our customer’s current contamination controls, developing enhanced cleanroom procedures and training cleanroom personnel, we keep our customers ahead of problems and way from crisis.

Testing Services

- Airborne particle count for classification of the installation and test measurement

- Airflow test

- Air pressure difference test

- Installed filter system leakage test

- Flow visualization

- Airflow direction test

- Temperature test

- Humidity test

- Recovery test

- Containment leak test

Difference Between Cleanroom Certification and Monitoring

Many people are confused about the difference between cleanroom certification and cleanroom monitoring. But their requirements and standards make them distinctly dissimilar/different.

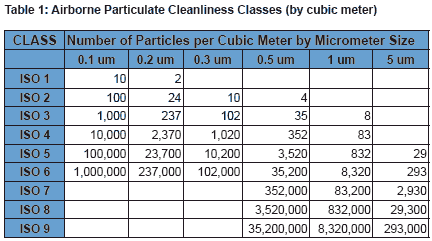

A cleanroom is essentially a modular environment in which various factors are kept under strict control, including airborne contaminants, the temperature, relative humidity, differential pressure and static electricity. In addition, cleanrooms are evaluated based on several levels of cleanliness referred to as classes.

When a cleanroom is certified to a certain class, it must operate according to standards that meet or exceed the performance of that class under a specific occupancy status.

Certification vs. Monitoring

Cleanroom certification, essentially, involves checking the room for various parameters to ensure that it is built to a specific set of requirements. The room is also routinely retested to the same factors to ensure the standards have not changed.

On the other hand, cleanroom monitoring applies a broader approach. The monitoring of a cleanroom is done to ensure that:

- The cleanroom parameters have not changed in any way. All aspects of the construction and supporting equipment are fully operational and performing at the same level as when the room was certified,

- The process in the room is in control at all times, and

- Individuals using the cleanroom always follow accepted procedures.

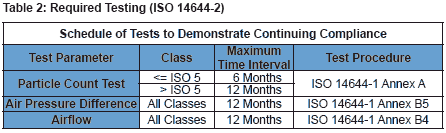

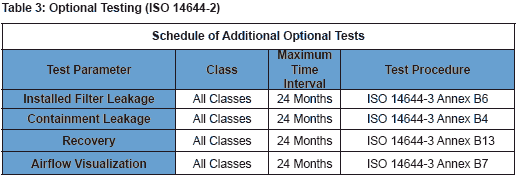

Cleanroom classification and class limits are established in ISO 14644-1. However, specifications for testing and monitoring to prove continued compliance are covered in ISO 14644-2. More specifically, ISO 14644-2 determines the type and frequency of testing required to conform to the standard. Some tests are mandatory; others are optional.

Compliance Demonstration

ISO 14644-2 also dictates that cleanroom particle classifications in areas cleaner than ISO class 5 require a time interval of at least six months between demonstrations of adherence to ISO 14644-1. And any areas that are less clean than ISO Class 5 require a 12-month maximum interval between displays of compliance.

In practical terms, demonstrations of compliance may be done more frequently than the maximum intervals specified in ISO 14644-2. The more often a show of compliance takes place, the smaller the loss of time and materials in the case of compliance failure. But if a cleanroom does not meet its designated standard, this can create a problematic situation. The quality of all products or processes performed in that area since the last demonstration of compliance will be suspect.

Maintaining a Constant Monitoring Plan

If an ongoing monitoring plan is developed for airborne particles and air pressure differential, changes can be made to the schedule of the particle counting certification testing. The monitoring plan should be determined by a risk assessment based on the type of facility, possible causes of contamination and impact of corruption on the product or process performed in the facility.

Keep in mind that it’s impractical and expensive to create minimum monitoring points based solely on the area of room in square meters. This approach works in certification, but coverage and testing guidelines must be established regardless of process and risk assessment. However, in a monitoring program, risk assessment is critical to determining what and where to monitor.

To make better choices about what and where particle monitoring should be performed, you should enhance your experience with different tooling and facilities, as well as your understanding of particle generation and cleanroom particle counters.